Our product

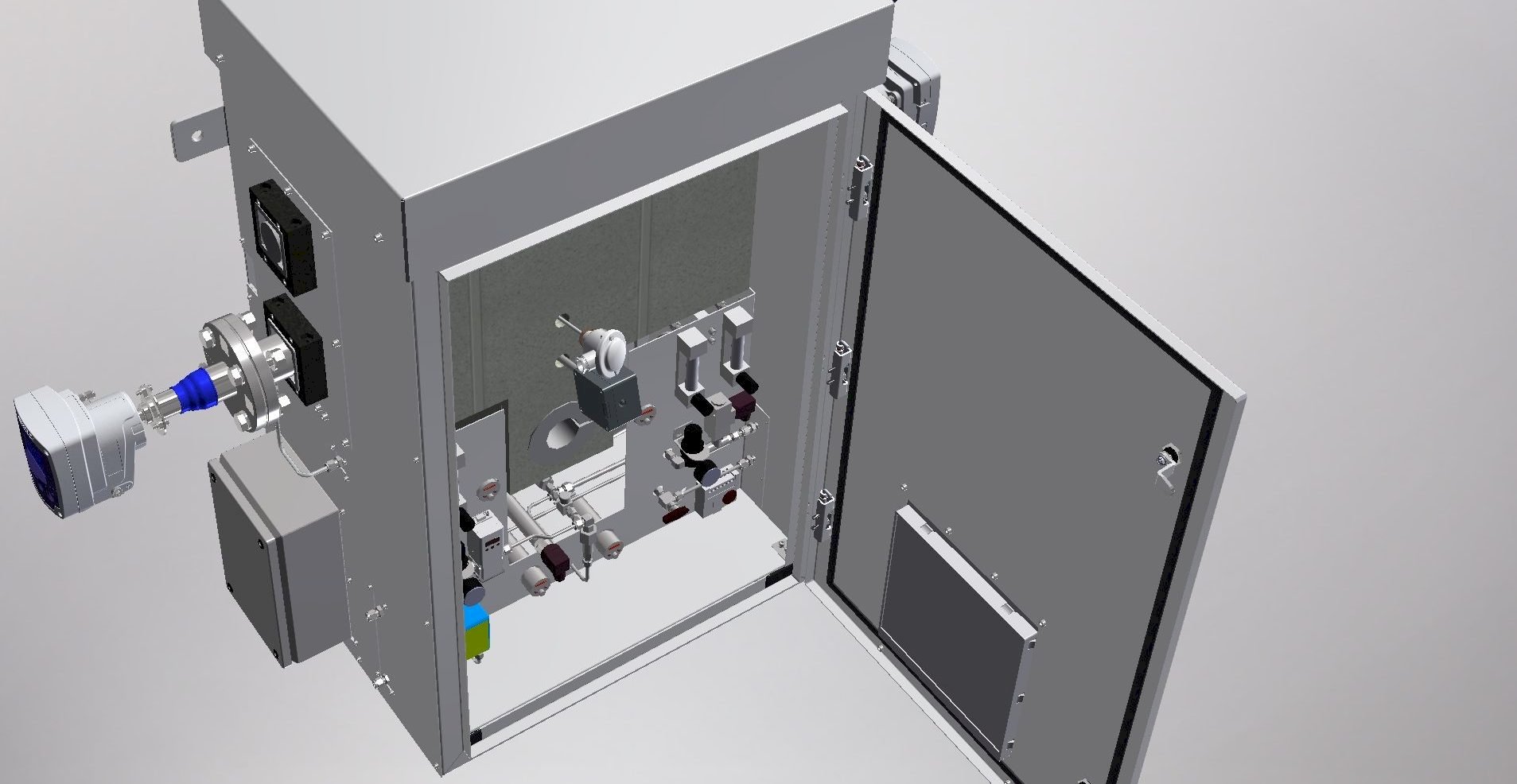

The Hybrid 600 features

- Bypass loop for fast laser gas analysis

- Small footprint of 1,05 x 0,82 x 0,55 m (HxWxD)

- Custom-made filter technology for high dust loads

- Patented non-contact laser design (air knife)

- Field installation doesn’t require housing

It is well known that large-scale combustion processes are hazardous. The emissions they produce are dangerous and often come with high-dust environments. Traditionally, laser gas analysers can prove inadequate in high-dust loads because of the laser’s inability to see through all of the airborne particles, making gas readings unreliable.

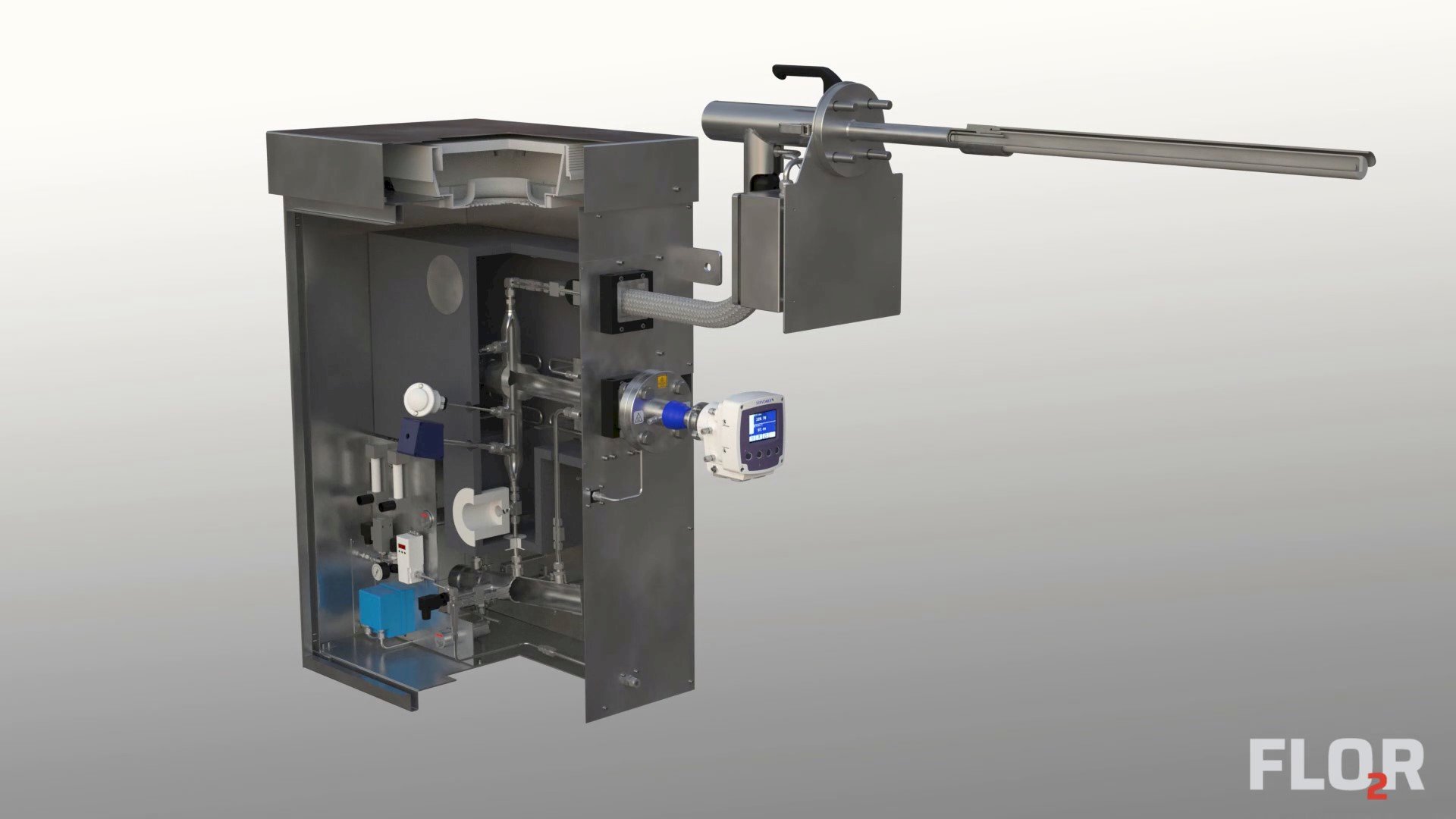

The Hybrid 600 offers the unique combination of an ‘air knife’ and a high-speed bypass loop. It is also a simple solution – but still flexible enough to work with any commercial laser brand.

Non-contact laser technology is better

The air knife is state-of-the-art technology that keeps the optic lenses clear of contamination from process gases. Quick and clean bursts of air flow past the lenses in a bypass loop system offering precise gas analysis. The bypass loop creates a fixed and controlled environment to analyse a sample of the gas, making it easier for the laser to work. It removes any uncertainties for an accurate reading with deviations of less than + 2 percent. A custom-made probe filter allows the bypass loop to operate in high-dust processes.

The Hybrid 600 can tolerate dust loads up to 200g/m3 with a response time of less than five seconds. Our fast and reliable non-contact laser technology gives you and your customers peace of mind when it comes to safety.

A simple solution for combustion processes

The Hybrid 600 has a compact design for fast and easy installation with low accompanying footprint. Full commissioning and testing can be completed in one day, resulting in reduced costly production downtime.

Because the bypass loop system creates a controlled environment, the gas analyser materials are not exposed to constant heat and pressure stress. So there’s no need for laser alignment. Adding further to its simplicity, the laser gas analyser technology is low maintenance, requiring calibration only once a year. As an in-situ solution, it is placed where the process gas is.